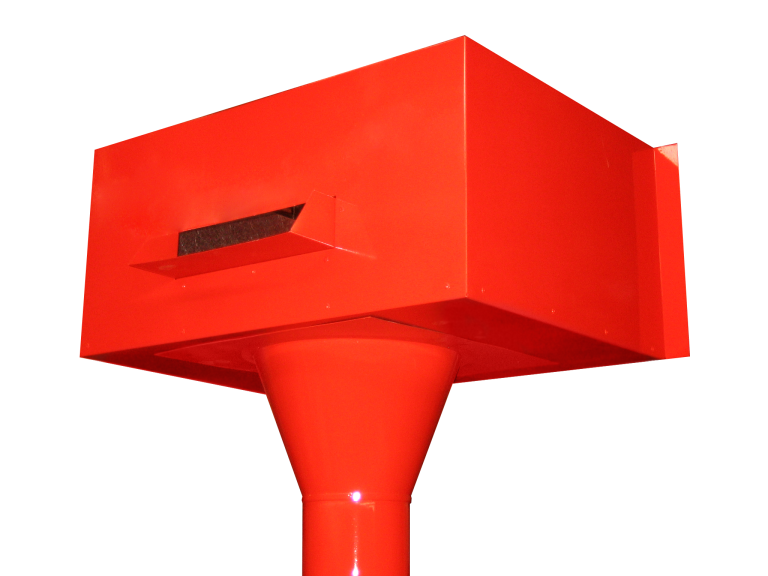

Hopper box for the evacuation of abundant rainwater

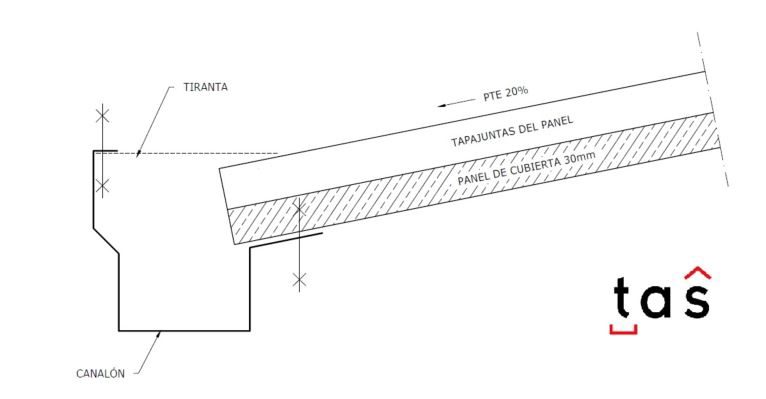

Problems with the evacuation of rainwater during intense rainfall in a short period of time? The rain water hopper box plays a very important role in keeping an industrial building free from dampness and water. So much so that an increasing number of newly constructed industrial warehouses incorporate this solution into their facades to assist in the drainage of rainwater. What is a rain water hopper box and how does it work? It is a custom-made metal element designed to handle a significant amount of water in a short period without compromising the proper functioning of the water drainage system. The rain water hopper box is positioned at the top of the facade to connect it with the gutter and effectively channel the flow of water from the roof to the ground. It receives water through the “rear lid” and discharges it through the downspout connected at the bottom of the hopper box. Custom manufacturing of rain water hopper box Thanks to the custom manufacturing of the rain water hopper box, various optional elements can be incorporated, such as the overflow or the top cover with opening. The overflow is located at the front of the hopper box to directly discharge water to the ground in cases where the water flow is very high. On the other hand, the top cover with opening facilitates the maintenance and cleaning of the rainwater drainage system. The “rear lid” is usually supplied blank, and the installer perforates it on-site to allow for some flexibility when connecting it to the gutter. The TAS rain water hopper box is manufactured in galvanized and precoated steel with thicknesses ranging from 0.6 mm to 1 mm, or in post-coated 1.5 mm galvanized steel. Therefore, it is a durable solution with excellent resistance to corrosion, temperature fluctuations, and prolonged exposure to the sun, in contrast to other materials such as PVC. The accessories of the rain water hopper box At TAS, we manufacture all the necessary accessories and elements for the proper drainage of rainwater from the roof to the ground. Dimension and maintenance of the water drainage system. It is important to ensure that the rain water hopper box are correctly sized and positioned according to the characteristics of the water catchment area and expected rainfall conditions. Additionally, regular maintenance and cleaning should be carried out to ensure there are no obstructions in the water drainage system that could compromise proper functioning. Solving the waterproofing of industrial buildings since 2005. At TAS, we have been providing metal solutions for over 15 years to prevent water leaks and dampness in buildings of all kinds. Therefore, we offer a comprehensive solution for roof enclosures, facades, and water drainage, focused on keeping buildings free from water.