3 factors to take into account for the ventilation of industrial buildings

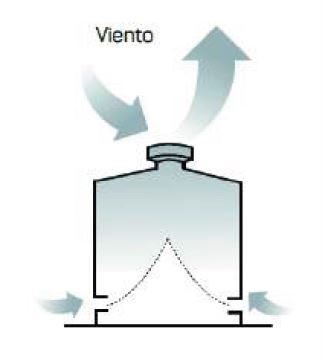

Discover in this article the basic principles on the ventilation of industrial buildings and other types of buildings. When we talk about the ventilation of industrial buildings, various factors must be taken into account that can affect its performance. Given the importance of having an optimal ventilation system in an industrial space, the study and prior planning of all the related elements will be key. Before going on to describe and comment on each of these factors, we must understand how the ventilation of industrial buildings works: “The fundamental principle of the ventilation of an industrial building is that the heat that is generated must be evacuated through the difference in temperature of the fresh air that enters through the low level and the stale air that is evacuated through the high level.” Taking this concept into account, we will now describe what must be taken into account when planning an optimal static or dynamic ventilation system. 1. What activity will be carried out inside the industrial warehouse? This is probably the first question that we must clarify, since the number of air changes per hour should be projected based on the needs of the industry that develops inside, as well as based on whether there will be people or animals in the room inside. In this sense, the “General Ordinance on Safety and Hygiene at Work” speaks of a minimum of 6 renewals per hour where there are workers. Depending on the activity that is carried out and based on the experience of both the Profilers Union, the Arcelor Group and our own, we have created a table of recommendations with a maximum and minimum value that allows us to adapt to different types and constructions beyond warehouses: If you don’t know how to reach the recommended number of renewals per hour, don’t worry. At TAS we can help you through a personalized ventilation study to choose the ventilation system for industrial buildings that best suits your project and meets this recommendation. 2. Air inlet through the low level or facade The volume of air that will enter the facility through the lower elevation must be planned and estimated. The number of air changes per hour that can be achieved will depend on the volume of air that can be introduced from the lower level. To manage the entry of air through the low level, we must take into account the size of the doors of the building, as well as anticipate whether these doors will normally remain closed or open. In the event that the doors are to be normally closed or their dimensions are not sufficient to achieve optimal ventilation, the installation of TAS ventilation grills should be planned to guarantee the entry of fresh air. 3. Air outlet through the high or covered level It will be just as important to project and estimate the flow of fresh air that enters through the low level as it is to anticipate the volume of stale air that can be evacuated through the high or covered level. In this way, the real needs for air evacuation must be considered to plan what type of ventilation system for industrial buildings will best fit and what number of fans should be used. In this sense, for the evacuation of stale air through the deck or roof, there are two main options: Point ventilation: it is achieved by installing aerators or extractors at different points on the roof, the operation of which is based either on wind energy (industrial wind aerator), on electrical energy (dynamic or forced aerator) or on a hybrid system that combines wind energy and electricity (Venturi aerator). Linear ventilation: it is achieved through linear fans (AIR-TAS) installed in the highest part of the roof, or ridge. These linear fans or aerators are installed over holes or cavities made in the roof itself and are designed to constantly evacuate stale air based on the pressure difference. We hope we have helped you with this entry on the ventilation of industrial buildings and buildings in general. Do not hesitate to contact us in case you have a ventilation project for an industrial building or need help with our customized study of ventilation for industrial buildings.