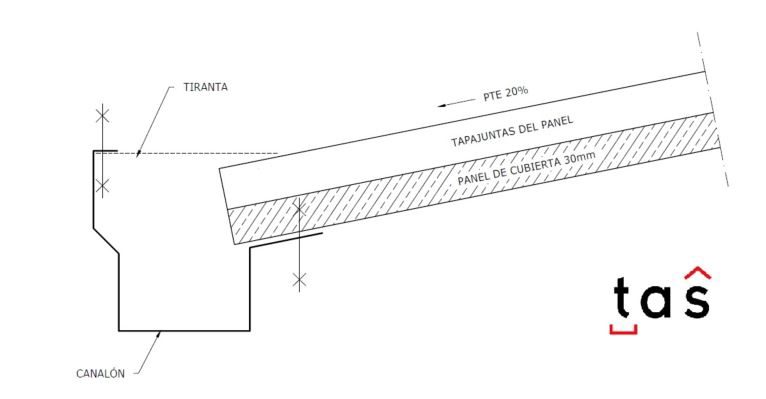

Custom-made steel gutter

The gutter from TAS. Experience and facilities in the manufacturing of this solution. The steel gutter for the conveyance and evacuation of rainwater is an essential element in any building. At TAS, we are experts in the manufacturing of custom gutters, whether in galvanized steel or pre-coated steel, as we will tell you below. Tongue-and-groove steel gutter. The ultimate solution. The steel gutter is a solution that we have been working on since our inception, accumulating a high level of knowledge and experience. One of the most sophisticated variants of this solution that we can manufacture at TAS is the tongue-and-groove conical gutter with a development of 1,500 mm and a length of 8 meters in thicknesses ranging from 0.8 to 2 mm. This gutter is designed for buildings with large roofs that, therefore, require the evacuation of large amounts of water in a short period. Thanks to its extensive development, it has a high capacity to evacuate a large water flow. Innovation of the gutter up to 8 meters The innovation in TAS gutter lies in its conical and tongue-and-groove manufacturing. Its conical geometry provides a slope that facilitates water runoff, while the tongue-and-groove design ensures a better overlap between different sections of the gutter, guaranteeing greater tightness and durability. Its production of up to 8 meters in length provides a more efficient solution since fewer joints are required, reducing the likelihood of leaks and saving time and money in installation. The TAS gutter type Our extensive experience in the manufacturing of this solution has helped us develop a standard type gutter. This gutter has dimensions suitable for a wide range of buildings and is usually the most requested for distribution and commercialization. The TAS standard type gutter is made of steel and is designed with an enhanced aesthetic. It is manufactured with a tongue-and-groove configuration and has a development of 416 mm. Over 15 years manufacturing steel solutions. At TAS, we are experts in rainwater drainage with steel, including not only gutters but also other accessories such as downspouts, nozzles, elbows, or even rain water hopper box. Contact us, and we will try to provide you with the best solution.