5 benefits of metallic cladding for the outer layer of your ventilated facade

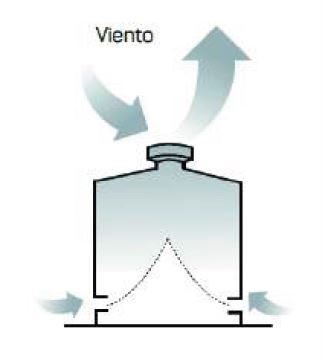

The ventilated facade built with a metallic cladding system brings great benefits. We tell you about them in this article! A ventilated facade is an exterior cladding system used in building to improve thermal insulation, moisture control, and the aesthetic appearance of the facade. The ventilated facade can be made of metallic cladding to improve its performance, as we will tell you in the following lines. Metallic cladding for the layers of a ventilated facade The lining of a ventilated facade consists of several layers. The base layer is the building structure, followed by an insulating layer that helps improve the buildings energy efficiency by reducing heat loss in winter and heat gain in summer. An air chamber is installed on top of the insulation that allows air to circulate between the facade and the exterior cladding. This helps regulate the temperature and wick away any moisture that may accumulate between the layers. The outer layer is the coating itself, which can be made of different materials and is visible. In this sense, whenever steel is chosen for the exterior cladding of a ventilated facade, we will ensure the following benefits: Benefits of an external metallic cladding on your metal facade Durability: Steel is a very resistant and durable material, capable of withstanding the most adverse weather conditions. wide range of possibilities to modulate the aesthetics of the facade. Appealing Aesthetics: Modern, sleek look. It can be used in different ways, playing with geometry or even in three-dimensional shapes, allowing for a wide variety of architectural designs. Lightness: Despite its strength, steel is a relatively lightweight material compared to other cladding, which makes it easy to install and reduces the structural load on the building. Reduced Maintenance: Steel liners require minimal maintenance, extending their life and reducing the need for frequent repairs and refinishing. Versatility: Steel can be molded and adapted to different shapes and sizes, which allows great flexibility in the design of the façade. Furthermore, it is compatible with other cladding materials, allowing it to be combined with glass, wood or other materials to achieve interesting visual effects. At TAS we are manufacturers of exterior metallic cladding for ventilated facades made of steel, aluminum, zinc or other metals. We have a wide range of architectural profiles for the cladding of this type of facades and we can manufacture an infinite number of options of metal sheets by varying their geometry. Do you want us to study your project? Count on us.