Folded metal sheet for facades: Elegance and Resistance in Architecture

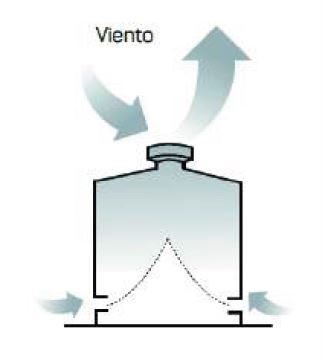

Learn about all the benefits of using folded metal sheets to cover and give character to the facade of a building. Folded sheet metal for facades is a material used for facade cladding due to its elegance, versatility and resistance. The bending technique of the metal – whether steel, aluminum, or zinc to name a few examples – creates an attractive visual effect and provides a durable solution for exterior cladding. In this article, we will explore the features, benefits, and applications of folded sheet metal applied to architectural facades. Characteristics of the folded metal sheet for facades The folded sheet metal usually comes in most cases from coils that are unrolled and cut to the length and width necessary for the project in question. Once the sheets are cut from the coil, they are ready to be perforated if necessary, or directly bended. The folds are made in special machines designed for this function called «folders». In this sense, there are manual folding machines that work in a single direction and automatic folding machines that are capable of folding on both sides, which makes the folding process much easier and faster. The process of generating folds in the sheet to varying degrees and at varying distances from one another creates a visually appealing geometry and texture. Furthermore, these folds not only add an aesthetic element to the facade, but also increase the rigidity and strength of the material. Benefits of folded sheet metal for facades: Sleek and modern aesthetics: The pleat pattern in the sheet metal provides a distinctive and contemporary look to the building’s facade. The variety of shapes and sizes of folds allows the creation of unique and personalized designs, adapted to architectural tastes and needs. Durability and resistance: Metal is a highly resistant and durable material, capable of withstanding adverse weather conditions and resisting corrosion. Folded steel or aluminum sheet metal retains these properties well, ensuring the longevity and reduced maintenance of the exterior cladding. Versatility in design: Folded sheet metal can be used in a variety of facade applications, including commercial, residential and public building cladding. Its flexibility allows it to adapt to different shapes and architectural geometries, creating a dynamic and attractive appearance. Energy efficiency: By combining the folded sheet metal with insulating materials, the energy efficiency of the building is improved by increasing thermal insulation. This contributes to reduce the expense and energy in the interior conditioning of the building. At TAS we are experts with more than 15 years of experience in sheet metal folding. We are capable of folding metal sheets with a length of up to 8 meters and a thickness of 6 mm. We work a wide range of metals such as: Steel Aluminum Zinc corten steel Stainless steel Hot Rolled Steel TPO laminate Do you need a customized metal solution tailored to your project? Contact our team now and we will give you the best advice.