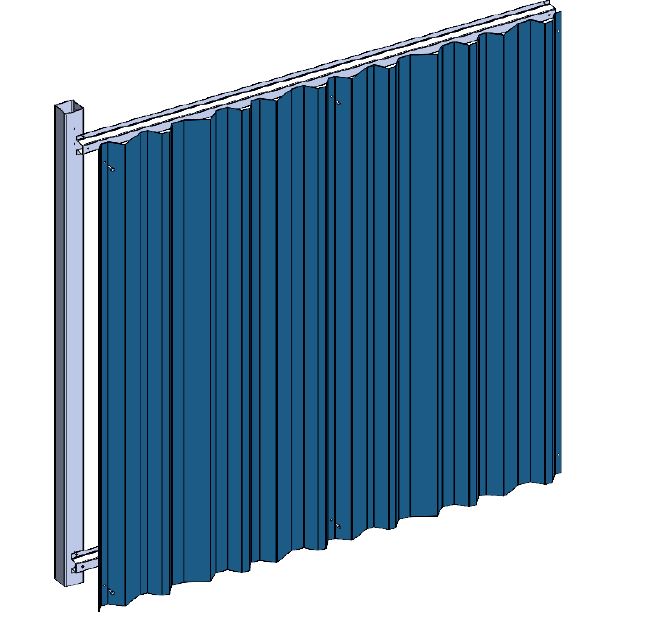

Sandwich sheet and sandwich panel are terms used in the construction and engineering industry to describe composite structures. Although both terms refer to internal and external skin panel systems, there are some differences between them. The sandwich sheet refers to a type of structure composed of two rigid external layers (usually metal) with an intermediate core of insulating material, such as polyurethane (PUR) or polyisocyanurate (PIR). These layers are joined together by a bonding or welding process, forming a strong and resistant structure. Sandwich sheets are commonly used in the construction of walls, ceilings and floors to provide thermal and acoustic insulation, as well as structural resistance. In principle, sandwich panel is a more general term that encompasses a variety of similar composite structures. Sandwich panels are also composed of outer layers and an insulating core, but they can be made of different materials, such as metal, wood, plastic, or fiberglass. These panels can have various applications in construction and industry, including facade cladding, roof coverings, doors, partition panels, among others. In short, the main difference lies in the terminology and scope of use. Sandwich sheet refers specifically to a structure composed of metal layers with an insulating core, while the term sandwich panel is broader and applies to various composite structures with different outer materials and insulating cores. Therefore, whenever we talk about a sandwich panel or sheet, we must not take anything for granted and specify or ask for specifications of the materials with which it has been manufactured. This way we will avoid misunderstandings and problems when consuming this architectural solution. At TAS we have more than 20 years of experience working with the PUR metal sandwich panel as well as its finishes for a perfect closing of facades and roofs. In addition, we have a large stock of these materials to be able to supply them immediately. Contact us for more information.