New metal profile for facades | Mallorca evolution

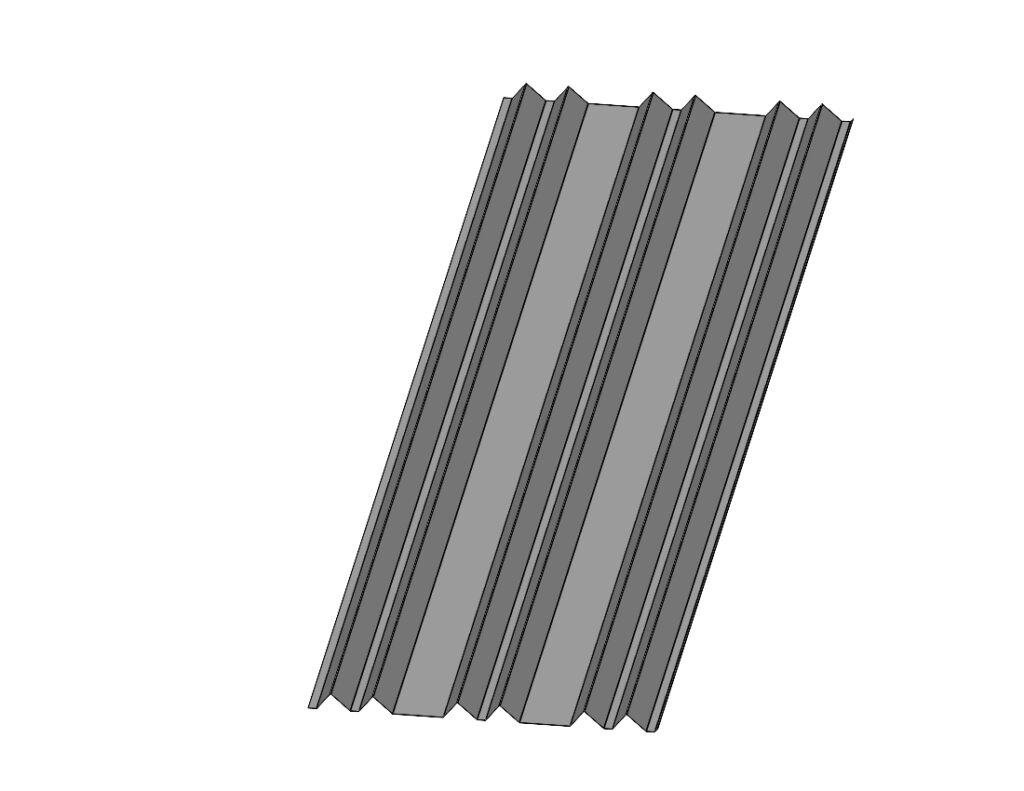

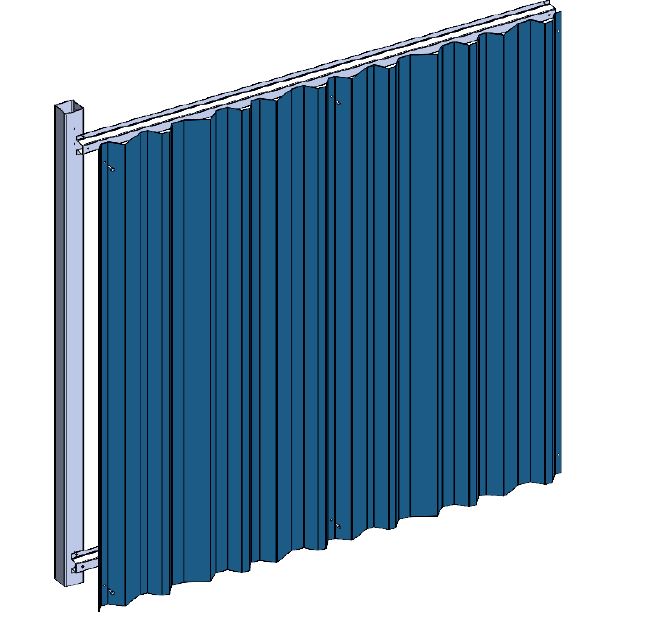

Learn more about the different modulating options offered by this new metal facade profile. Without a doubt, the most versatile profile ever designed. TAS is defined by the flexibility of its production process and by its innovative and avant-garde spirit. For this reason, at TAS we are pleased to be able to launch the Mallorca Evolution metallic facade profile on the market soon. Architectural metal profile sketch Versatility for metal facades The Mallorca Evolution profile can be manufactured from the Mallorca 6, 7 or 8 Profile, and offers endless possibilities when it comes to modulating a facade. It adapts perfectly to specific projects in which originality is sought in the texturing of the facade, modifying the number of folds and the distance between them. Below is a possibility that could be achieved by combining different Mallorca Evolution options: Variety of materials for the manufacture of metal profiles This profile can be manufactured in steel, aluminum or zinc and can reach a maximum length of 6 meters. Undoubtedly, an ideal option for architects, designers and technicians looking for a unique metal enclosure. Count on TAS for your metal facade project. Do not hesitate to contact us so that we can study your project and offer you the best construction solution.